Pneumatic Butterfly Valve, Automatic Control Valve

Product Characteristics

Advantages of pneumatic soft sealing butterfly valve:

1. The structure is simple, the flow resistance coefficient is small, the flow characteristics tend to be straight, and no debris will be retained.

2. The connection between the butterfly plate and the valve stem adopts a pin-free structure, which overcomes the possible internal leakage point.

3. Divided into pneumatic wafer type soft sealing butterfly valve and pneumatic flange soft sealing butterfly valve to meet different pipelines.

4. The seals can be replaced, and the sealing performance is reliable and can achieve zero leakage of bidirectional sealing.

5. The sealing material is resistant to aging, corrosion and long service life.

Pneumatic soft sealing butterfly valve parameter description:

1.Nominal diameter: DN50~DN1200(mm).

2.Pressure class: PN1.0, 1.6, 2.5MPa.

3.Connection method: Wafer or flange connection.

4.Spool form: disc type.

5.Drive mode: Air source drive, compressed air 5~7bar (with hand wheel).

6.Action range: 0~90°.

7.Sealing material: all kinds of rubber, PTFE.

8.Working occasion: Various corrosive media, etc. (normal temperature and pressure, low temperature and low pressure occasions).

9.Accessory options: positioner, solenoid valve, air filter pressure reducer, retainer valve, travel switch, valve position transmitter, handwheel mechanism, etc.

10.Control mode: switch two-position control, air-open, air-close, spring return, intelligent adjustment type (4-20mA analog signal).

Pneumatic hard sealing butterfly valve performance characteristics:

1. Adopting the triple eccentric principle structure, the valve seat and the disc plate have almost no friction when opening and closing, which improves the service life.

2. Unique structure, flexible operation, labor-saving, convenient, not affected by high or low pressure of medium, and reliable sealing performance.

3. It can be divided into pneumatic wafer type hard sealing butterfly valve and pneumatic flange hard sealing butterfly valve, which are suitable for different connection methods and are easy to install in the pipeline.

3. The sealing is composed of laminated soft and hard metal sheets, which has the dual advantages of metal sealing and elastic sealing, and has excellent sealing characteristics at low and high temperatures.

5. The butterfly valve is equipped with a sealing adjustment device. If the sealing performance decreases after long-term use, the original sealing performance can be restored by adjusting the disc sealing ring to approach the valve seat, which greatly improves the service life.

Technical parameters of pneumatic hard sealing butterfly valve:

1.Nominal diameter: DN50~DN1200(mm)

2.Pressure class: PN1.0, 1.6, 2.5, 4.0MPa

3.Connection method: wafer type, flange connection

4.Seal form: metal hard seal

5.Drive mode: air source drive, compressed air 5 ~ 7bar (with hand wheel)

6.Action range: 0~90°

7.Body material: carbon steel, stainless steel 304, stainless steel 316

8.Working conditions: water, steam, oil, acid corrosive, etc. (can be used in high pressure and high temperature applications)

9.Temperature range: Carbon steel: -29℃~450℃ Stainless steel: -40℃~450℃

10.Control mode: switch mode (two-position switch control, air-open, air-close), intelligent adjustment type (4-20mA analog signal), spring return.

Company Introduction

Wenzhou KGSY Intelligent Technology Co., Ltd. is aprofessional and high-tech manufacturer of valve intelligentcontrol accessories.The independently developed andmanufactured products main include valve limit switch box ( position monitoring indicator ), solenoid valve, air filter, pneumatic actuator, valve positioner, pneumatic ball valveetc, which are widely used in petroleum, chemical industry,natural gas, power, metallurgy, paper-making, foodstuff,pharmaceutical, water treatment etc.

KGSY has obtained a number of quality certification,such as: cCC, TUv, CE, ATEX, SIL3, IP67, Class cexplosion-proof, Class B explosion-proof and so on.

Certifications

Our Workshop

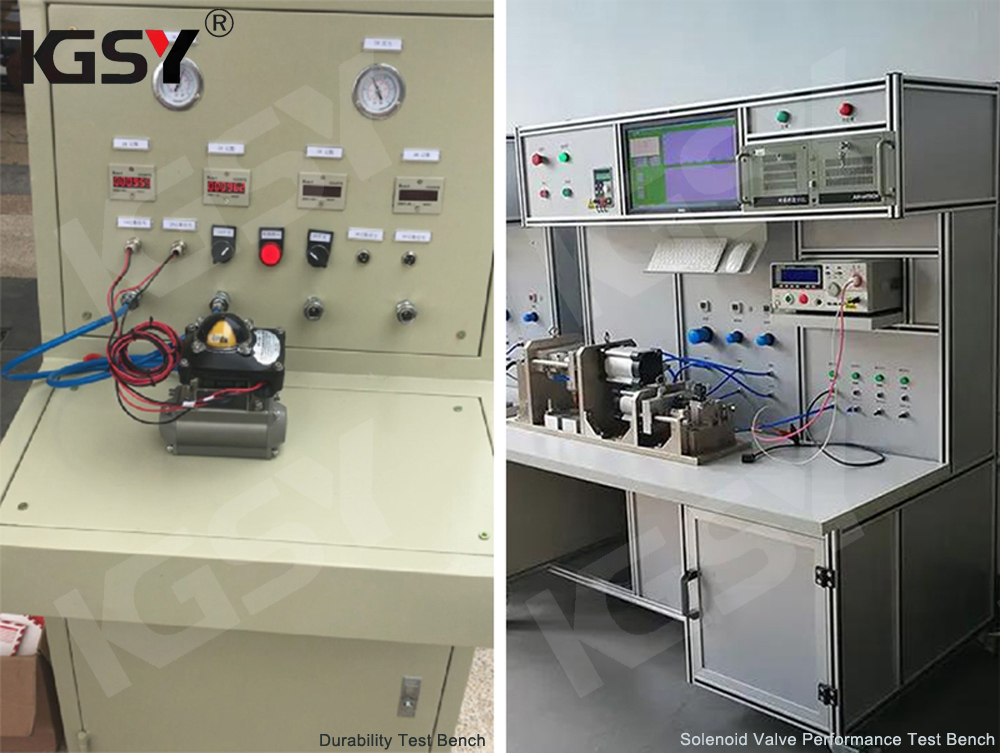

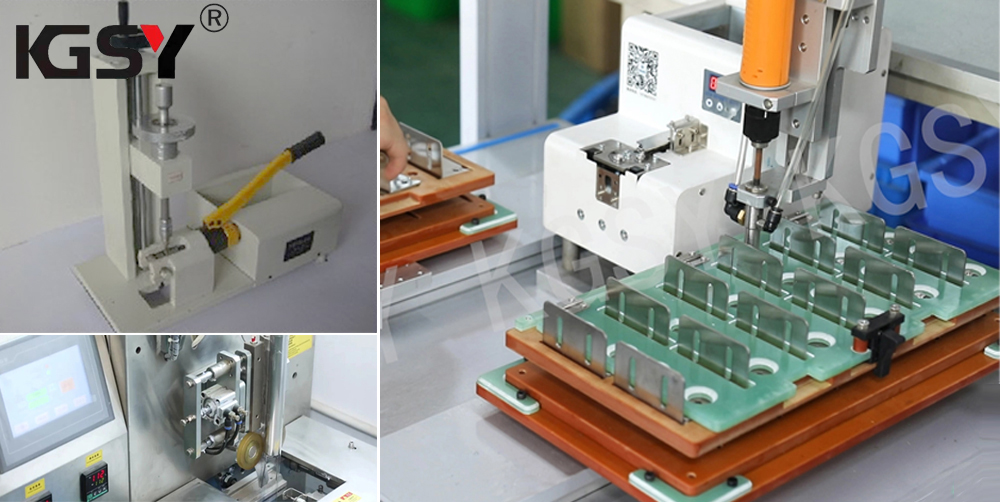

Our Quality Control Equipment